Are you confused about choosing a manufacturer for supply of your cable needs? In the practical world, the situation is tough. In the competitive world of today, there are numerous options available. Making a selection of the right company is important but poses to be a difficult decision to many.

Quality products

Medical device companies are subject to numerous stringent rules and regulations. The objective is to ensure delivery of top-notch quality products on a regular basis. You may browse peterstechnology for cost-effective medical cable assembly. Powerful quality management system ensures that the products meet all the industry standards.

Get professional help

The reputed organizations perform their activities in a supremely regulated manufacturing environment. The medical cable assembly, subassemblies, and numerous packaging requirements are handled in various clean rooms. The engineering groups of these manufacturing concerns work hand in hand with the customers. No matter how challenging your orders are, these professional people are capable of providing practical solutions.

Cost minimization

On your first consultation, you should bring your design. You should have a clear understanding of your specific needs. The engineering team will sit down with your designs and evaluate them. They will also assist in the refinement of those designs. They will also check and see if their company possesses the manufacturing capability. The objective is to ensure that products are designed and produced as per specifications along with cost minimization.

Customized services

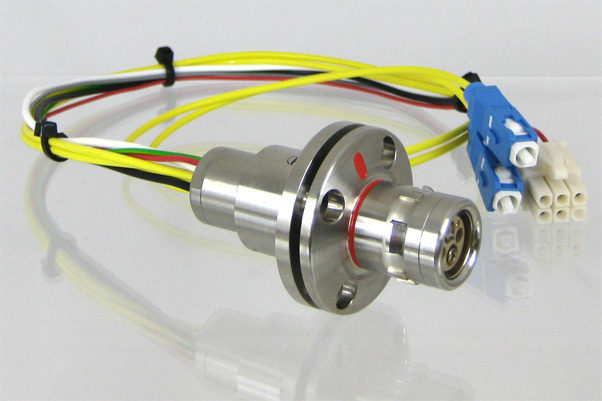

The requirements of customers are often met by giving customized services. A custom cable provides an opportunity to the designer to exercise his control on the color codes, tolerances, jacket materials and insulation. These types of designs also allow regulation on diameters so that the cable can be easily adjusted within ancillary components such as connectors and grips. It also ensures that poor quality cables are not used.

Size reduction

In previous days, many rooms had to be utilized to accommodate the various power supply and controls. However, in recent times, miniaturization of products is the popular trend. Now those machines are designed in such a way so that there is size reduction without compromising on the functional aspects. Most of the machines which used to be housed in multiple rooms are now fitted in a single room. Some of the consumer medical tools even can fit in the palm of your hands. This size reduction feature has many benefits. Those machines can be installed and stored in smaller spaces. Space-saving has helped in cost reduction to a significant extent.

Certifications and standards

The wires and cables used in medical devices should be tough to withstand repeated bending. They have to comply with rigid guidelines. These regulations vary with the possibilities of the patient in coming in close contact with these appliances. The more are the chances of the patient coming in close contact with these devices, the more stringent are the safety regulations. Select a company who can grasp your needs and are offering relevant solutions. Do not forget to examine their certifications and standards. Quality should be a top most priority for a good manufacturer.

Blog Source: sites.google.com/site/peterstechnolgy/

0 comments:

Post a Comment