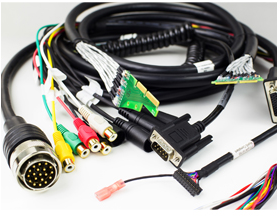

Image source: DSM&T

Although

the terms ‘cable assembly’ and ‘wire harness’ are used in place of each other,

they aren’t the same thing. The ever-existing confusion between both these

products is quite understandable. Most of the commercial facilities or

businesses use these terms interchangeably, which creates confusion about their

functionalities and applications.

While

there are not much difference in their basic functions, wire harnesses and

custom cable assemblies differ in terms of specialized attributes. Therefore,

it’s quite essential and important to understand the differences between these

products. That will help you develop an idea of their applications in

distinctive projects.

Significant

aspects to consider

Before

delving deep into understanding the characteristics of these two crucial

components, it will be imperative to know about other factors. Comprehending

the difference between cables and wires will be the key to understanding

differences between wire harnesses and cable assemblies.

·

Wires: These

are metal strands capable of conducting electricity. You can get them in

aluminum and copper.

·

Cables:

Cables happen to be the combination of numerous wires. It might be two or more

than that, and they are bonded together.

It’s

quite evident that both these components are different from each other. Quite

naturally, their functions and applications will also differ considerably. On

that note, it’s high time to take a look at the distinctive characteristics of a

custom wire harness and cable

assemblies.

Understanding

the difference

According

to market definition, wire harnesses are nothing but exterior sheath imparting

an external protection to cables and wires. On the other end, cable assemblies

are referred to as wires and cables bunched into a group.

It’s

here that we come across a crucial question. What is it that makes both these

components different? Let’s carry on with the discussion concerning the

following parameters:

1. The

manufacturing material

Wire

harnesses are manufactured from thermoset or thermoplastic, which imparts

optimum protection. Wire harnesses contain multiple cables with individual

coverings within a single harness.

When

it comes to cable assemblies, you will come across quite a few manufacturing

materials. From shrink-wrapped thermoplastics and vinyl to thermoplastic

rubber, cable assemblies are made out of various materials. Although cable

assemblies play a highly crucial role in organizing cables and wires, they find

application in diverse projects.

2. The

distinctive functionalities

In

spite of similar basic functions, both wire harnesses, and cable assemblies

have distinguished functionalities. While a wire harness finds its perfect

application in electrical contracts and engineering projects, the custom cable

assembly is used to impart protection to home wiring systems.

Cable

assemblies shield individual wires and ensure optimum protection against

abrasion, compression, friction, moisture, and several other accidents. On the

other end, wire harnesses emerge as low-cost solutions for protection against

temperature swings.

Concluding

thoughts

With these

distinctive functionalities and applications, wire harnesses and custom cable

assemblies seem to be quite different from each other. However, planning your custom wire

harness purchase with pioneering manufacturers like Peter’s Technology will

be the best thing to do. You will get certified and tested

products, adhering to topmost quality standards.

Resource:https://peterstechnology.wordpress.com/2016/10/19/wire-harness-vs-cable-assembly-whats-the-difference/

Resource:https://peterstechnology.wordpress.com/2016/10/19/wire-harness-vs-cable-assembly-whats-the-difference/