Do you have a requirement for custom coil cord? Regardless of your application, such a customized solution can be provided by some of the reputed cable manufacturers. A specialized manufacturer will give you a patient hearing about your wiring requirements. This will give them a scope to make the best of suggestions regarding the materials. The ultimate objective is to ensure that the finished wire can meet the requirements of your equipment.

Customized to suit specific needs

The field of medical devices is becoming complex day by day. Custom cable manufacturing assemblies are a popular choice among the customers in recent times. Of course, the types vary from industry to industry. In the medical sectors, these devices are, required to be not only trustworthy from all angles but they must be in a position to withstand any sterilization process. They must be biologically compatible with all aspects. It is an expert manufacturer who can provide you guidance for your specific requirements.

Different kinds of wiring needs

Many factors play an impact on the choice of types of materials for medical devices. Some of these factors are the purposes for which they are intended and the operating requirements. You may need standard electrical wires which are mainly used in the internal wiring of the tool for various applications. Such tools do not need to be in close contact with patients, and they do not require sterilization of any kind. Super flexible wires may be needed in some situations for installation in extremely small devices. So the use of custom cable manufacturing is quite common nowadays, as you can see in the website of peterstechnology.

Understanding your needs

Special emphasis must be placed on the utilization of high-quality wires. If the wires are defective, then the final products will be of poor quality. So it is of utmost importance to buy a wire harness from a well-known service provider. Professional electricians are needed to install them correctly; otherwise, the machines will not be able to operate smoothly. You have to develop an understanding of your product’s application. This will help your manufacturer in making the right choice of materials for your medical devices.

Significant progress in the field of wiring

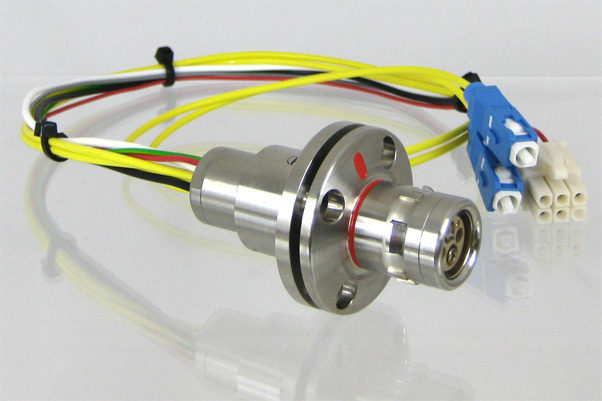

With rapid advancement in the medical sector, there has been significant progress made in associated segments too such as wiring. In the previous days, there was a general tendency to overlook this specific aspect. As a result, there was unnecessary delay in the designing process. Custom designs allow an opportunity to exercise control over conductor counts, tolerances, insulations and jacket materials. Even diameters could be controlled in such a way so that ancillary components such as grips and connectors could be adjusted easily in the cables. Miniaturization of products is the recent trend noted in the medical field. This has paved the way for utilization of smaller wires. The reduction of distance proves to be quite beneficial because now these cables can be bent more easily. Selection of the right vendor is essential for the faster realization of the project.

Blog Source: sites.google.com/site/peterstechnolgy/