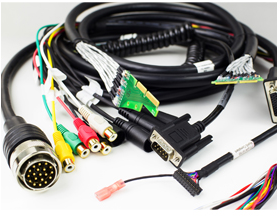

Cable

assemblies find application in various projects across industrial operations.

From construction sites to medical sector, these cable assemblies are used in

numerous applications. However, there’s a crucial point worth considering in

this context. Cable assemblies have diverse uses. Depending on the specific

project needs and requirements, these cables exhibit distinctive

functionalities.

Knowing

about the materials happens to be of paramount significance. Especially, when

it comes to medical cable assemblies,

the jacketing material seems to be an important aspect to consider. Take a look

at these significant factors associated with the quality of jacketing

materials.

Crucial

factors to consider

The

jacketing material not only imparts protection to the cable assembly but also

ensures strength and durability. Most importantly, these materials also act as

insulating agents and conductors. Some of the highly important factors include:

·

Durability:

When it boils down to choosing jacketing materials for cable assemblies,

durability emerges as a prime requisite. You simply can’t imagine a custom

cable assembly without a proper outer covering or jacket. The best jacketing

material will enhance the durability of cable assemblies alongside imparting

strength to it.

·

Flexibility:

Since they find applications in diverse tasks and processes, flexibility is an

important requisite for medical assemblies. None other than the jacketing

material imparts flexibility to these cable assemblies thus making them apt for

medical projects.

·

Leakage-resistant:

Cable assemblies used in the medical sector should offer perfect leakage

resistance. It’s the jacketing material that ensures complete protection

against leakage.

·

Contact-friendly:

It is quite obvious that these cable assemblies will come in contact with

patients. Therefore, suitability to human contact will turn out to be a crucial

aspect.

While

choosing the jacketing materials, you must have these aspects in mind. Planning your purchases

with leading medical cable assembly manufacturers like Peter’s Technology

will fetch you the top quality products.

Why

is the jacketing material important?

Cable

jackets happen to be important in ways more than one. If you take a look at its

functions, you will come across the following aspects.

The

jacketing material in healthcare cable assemblies acts as insulation,

isolation, and protection agent. It ensures complete protection for the human

body and also prevents conducting wires from coming into contact with it. Quite

naturally, jacketing materials in these custom cable assemblies are critical to

the functioning of high-end medical devices as well as protection of the human

body.

If

you are planning for a medical device cable purchase, take a look at these key

factors associated with the project.

Biocompatibility

Custom

cable assemblies built for medical purposes have to be biocompatible. Since

these assemblies find application in various operations and come in contact

with your body, biocompatibility is not just an option, but a crucial

necessity.

When

it comes to choosing materials for this jacket, none other than silicone proves

to be the best option. By ensuring compatibility, easy sterilization, cleaning,

and disinfection, silicone turns out to be the most effective jacketing material.

Parting

thoughts

Medical

device assemblies are of paramount significance for innumerable processes,

tasks, and projects in the healthcare sector. Always perform quality checks on

the jacketing material thus finding out top-quality products.

0 comments:

Post a Comment